Release agents are crucial auxiliary materials in industrial production, primarily used to prevent sticking between molds and molded products, ensuring a smooth surface and easy demolding of the finished product. Whether in plastics, rubber, composites, casting, or glass manufacturing, release agents play a vital role. Their main functions include reducing mold wear, extending mold life, improving production efficiency, and ensuring product quality. There are various types of release agents, categorized by their chemical composition and physical properties, such as silicone-based, oil-based, wax-based, and water-based agents. Recently, albite, a mineral, has shown unique advantages in the application of release agents, garnering significant industry attention.

The Role of Release Agents

The primary function of release agents is to form a thin film that minimizes friction between the mold and the product, facilitating easy demolding. Additionally, high-quality release agents provide lubrication, preventing mold surface wear and corrosion, ensuring the precision and longevity of the mold. Release agents also improve the surface quality of products, reducing defects, and enhancing the aesthetics and consistency of finished goods. In specific manufacturing processes, release agents help control the size and shape of products, meeting higher production standards.

Advantages of Using Albite as a Release Agent

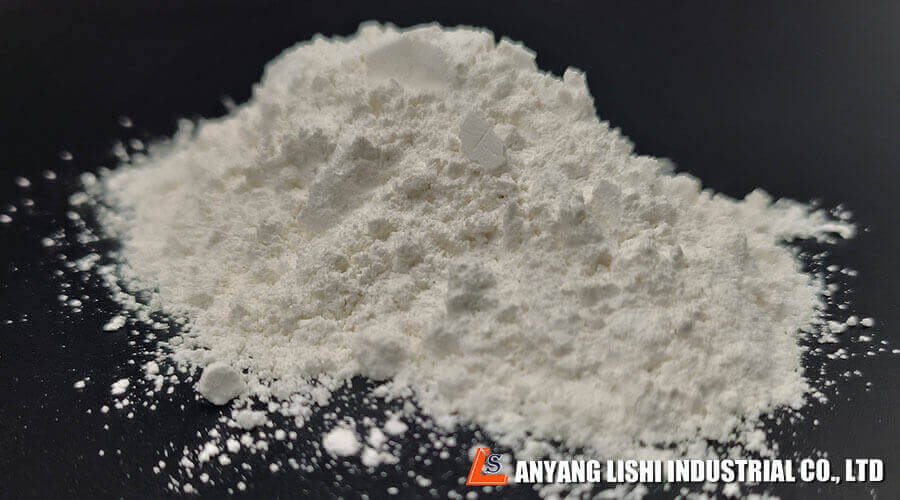

Albite (NaAlSi3O8) is an aluminosilicate mineral known for its high chemical stability, excellent thermal stability, and superior lubricity, making it an ideal material for release agents.

1. High Chemical Stability

Albite powder exhibits outstanding chemical inertness, remaining stable in high-temperature and various chemical environments. This characteristic allows it to be used long-term in different industrial settings without degradation or failure, ensuring the continuous effectiveness of the release agent. This is particularly important for molds operating in high-temperature or chemically corrosive environments, such as metal casting and glass forming industries.

2. Excellent Thermal Stability

With a low coefficient of thermal expansion, albite maintains its structure and functionality in high-temperature environments. This property prevents the release agent from detaching or degrading due to thermal expansion, enhancing production stability and product quality consistency in high-temperature mold applications.

3. Superior Lubricity

The smooth surface of albite provides excellent lubricating properties, significantly reducing the friction coefficient between the mold and the product. This not only improves demolding efficiency but also reduces mold wear, extending the mold’s service life and lowering production costs. Additionally, albite powder’s lubricity results in smoother, more polished product surfaces, enhancing the product’s aesthetic quality.

4. Environmental and Safety Benefits

As a natural mineral, albite’s processing is relatively simple, with minimal environmental impact. Compared to some chemically synthesized release agents, albite is more environmentally friendly. Furthermore, albite is non-toxic and harmless, posing no adverse health effects on workers, meeting modern industrial requirements for environmental protection and safety.

5. Abundant Resources and Low Cost

Albite powder is abundantly available on Earth, with low extraction and processing costs. This makes it a highly economical raw material for release agents, effectively reducing production costs and enhancing the market competitiveness of enterprises.

Conclusion

As an emerging material for release agents, albite powder demonstrates significant application potential in industrial production due to its unique chemical stability, thermal stability, superior lubricity, environmental friendliness, and cost-effectiveness. With the continuous advancement of technology and increasing demands for production efficiency and product quality, the application prospects of albite in the field of release agents will be broader. Future research and practice will further optimize the use and effectiveness of albite, enabling it to play a more significant role in industrial production.