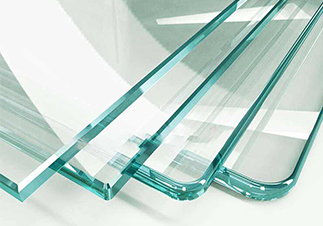

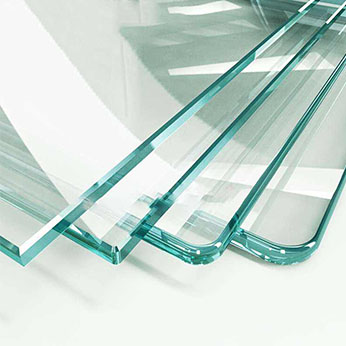

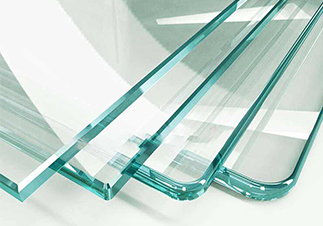

Sodium feldspar can provide Na2O as flux, Al2O3 and CaO as stabilizer sources, lowering the melting temperature and improving transparency and strength.

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.com

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.