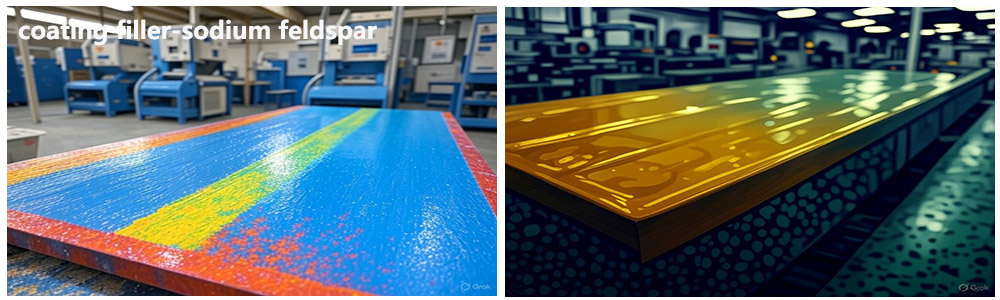

In the rapid development of the modern coatings industry, the selection of functional fillers has become one of the core technical paths to improve product performance and reduce costs. As an important representative of inorganic fillers, sodium feldspar plays an irreplaceable role in coating systems due to its unique physical and chemical properties. This article will explore in depth the definition and function of coating fillers and the unique value of sodium feldspar in the coatings industry.

Coating fillers refer to solid particulate substances added to the coating formula, usually inorganic minerals or synthetic materials. Their main function is to optimize the physical, chemical and application properties of the coating while reducing production costs.

The functions of fillers in coatings are diverse and crucial. First, fillers can effectively control costs by filling the volume of the coating system and reducing the proportion of expensive components such as resins. Second, fillers can significantly improve the mechanical properties of the coating, such as improving the hardness, wear resistance and scratch resistance of the coating film. In addition, fillers can also adjust the rheological properties of the coating, such as viscosity and fluidity, to ensure uniformity and stability during construction. In functional coatings, fillers can also give the coating special properties, such as antibacterial, anti-corrosion or heat insulation.

The selection of fillers requires a comprehensive consideration of their particle size, particle size distribution, chemical inertness, oil absorption value and compatibility with the base material. High-quality fillers should provide functional enhancements while minimizing the negative impact on the gloss, hiding power or weather resistance of the coating.

Sodium feldspar (NaAlSi₃O₈) is a sodium-containing aluminum silicate mineral that is widely found in the earth’s crust and is highly favored in the coatings industry due to its unique physical and chemical properties. Compared with other fillers, sodium feldspar has the following significant advantages:

Excellent chemical stability

Sodium feldspar exhibits high chemical inertness in acidic and alkaline environments and can effectively resist chemical erosion that the coating may encounter during use. This property makes it particularly important in outdoor architectural coatings and industrial anti-corrosion coatings, which can significantly extend the service life of the coating.

Good dispersibility and rheological control

The particle morphology of sodium feldspar is usually flake or needle-shaped, with uniform particle size distribution and low oil absorption. These characteristics give it good dispersibility in the coating system, which can effectively adjust the rheological behavior of the coating, prevent sedimentation and stratification, and ensure the flatness and consistency of the coating after construction.

Enhance the mechanical properties of the coating film

The high hardness and excellent wear resistance of sodium feldspar make it an ideal choice for enhancing the mechanical strength of the coating film. In highly abrasion-resistant coatings, sodium feldspar can significantly improve the scratch resistance and durability of the coating.

Cost-effectiveness and sustainability

Compared to some high-cost fillers, sodium feldspar is relatively cheap, abundant, easy to mine and process. This not only reduces the production cost of coatings, but also meets the current industry requirements for sustainable development.

Optimization of optical properties

The refractive index of sodium feldspar is similar to that of many resin base materials, which can reduce the light scattering of the coating, thereby improving the transparency or gloss of the coating film. This property is particularly important in high-gloss decorative coatings and varnishes.

As a coating filler, sodium feldspar is becoming a hot topic in the industry due to its advantages such as chemical stability, excellent performance and low cost. As a leading supplier, Henan Ankai New Materials Co., Ltd. continues to provide high-quality sodium feldspar products to help the innovative development of the coating industry. In the future, as environmental protection needs increase, the role of sodium feldspar in promoting green transformation will become more prominent.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.