Sodium feldspar, an alkali or alkali-earth metal aluminum silicate mineral with a non-hydrated framework structure, is essential for the ceramic and glass industries. Its stable chemical properties make it versatile, containing SiO2, Al2O3, Na2O, K2O, and CaO. Sodium feldspar plays a crucial role in glass and ceramic production by preventing crystallization, enhancing mechanical strength, and reducing material costs.

The types of impurities in sodium feldspar vary based on the ore deposit. Common harmful elements include iron and titanium, while impurity minerals comprise quartz, clay minerals, mica, hematite, magnetite, and goethite. Some ores may also contain pyrite, sillimanite, garnet, hornblende, biotite, tourmaline, and zircon.

Iron impurities in sodium feldspar ores manifest in various forms, such as hematite, magnetite, and goethite, either finely dispersed between feldspar particles or forming thin oxide films on the feldspar surface. Titanium impurities typically appear in the form of ilmenite and rutile.

Hand sorting is effective for coarse impurities in high-quality feldspar ores. Ore washing and desliming methods, using equipment like washing troughs or vibrating screens, help remove clay, mica, and fine particles, enhancing the ore’s quality.

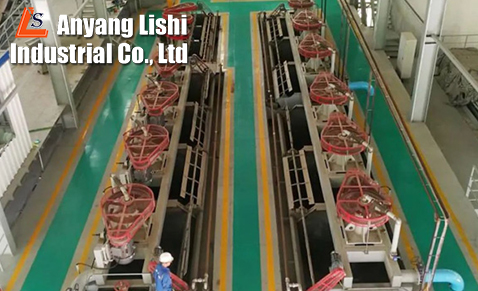

Magnetic separation is employed to remove iron-bearing minerals, such as hematite and magnetite. High-gradient magnetic separators, both dry and wet, are utilized to achieve effective separation.

Flotation is extensively used for separating feldspar from impurities like mica, quartz, iron-bearing minerals, and titanium minerals. Selective flotation agents, adjusting pH levels, and optimizing process conditions contribute to efficient separation.

Acid leaching with hydrochloric acid or sulfuric acid selectively dissolves iron-bearing minerals, particularly useful for ores with complex iron impurities. Careful control of reaction conditions is crucial.

Bioleaching is an eco-friendly method that utilizes microorganisms to selectively dissolve iron impurities, especially effective for finely disseminated iron. It is a sustainable approach with minimal environmental impact.

Combining various methods, such as magnetic separation followed by flotation or acid leaching, provides a comprehensive approach to achieve the desired purity level. Tailoring processes based on ore characteristics and purity requirements is essential.

In conclusion, the purification of sodium feldspar is a critical step to meet the quality demands of industries like ceramics and glass. Employing a combination of physical beneficiation, chemical methods, magnetic separation, flotation, acid leaching, and even innovative approaches like biological leaching ensures the effective removal of impurities. As industries evolve, researchers and practitioners continue to explore advanced techniques for sodium feldspar purification, aiming for improved efficiency and environmental sustainability.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.