LS sodium feldspar mines is located in Linzhou City, with a sodium feldspar resource of 1.5 million tons, Chemical elemente contents:

Al2O3 19-22%

SiO2 65%min

Fe2O3 0.1%±0.05

Na2O 11%±0.5

CaO 0.6%max

Whiteness 55°

It is a high-sodium, high-aluminum, low-iron sodium feldspar ore, We sincerely inviting deep cooperation with ceramic, glass, refractory materials, and other enterprises!

Sodium feldspar, with the chemical formula NaAlSi3O8, is an important mineral widely used in the glass and ceramic industries. Analyzing its mineral phases not only helps evaluate its purity and properties but also guides its applications in different industries. The following discussion will focus on the mineral phase analysis of sodium feldspar.

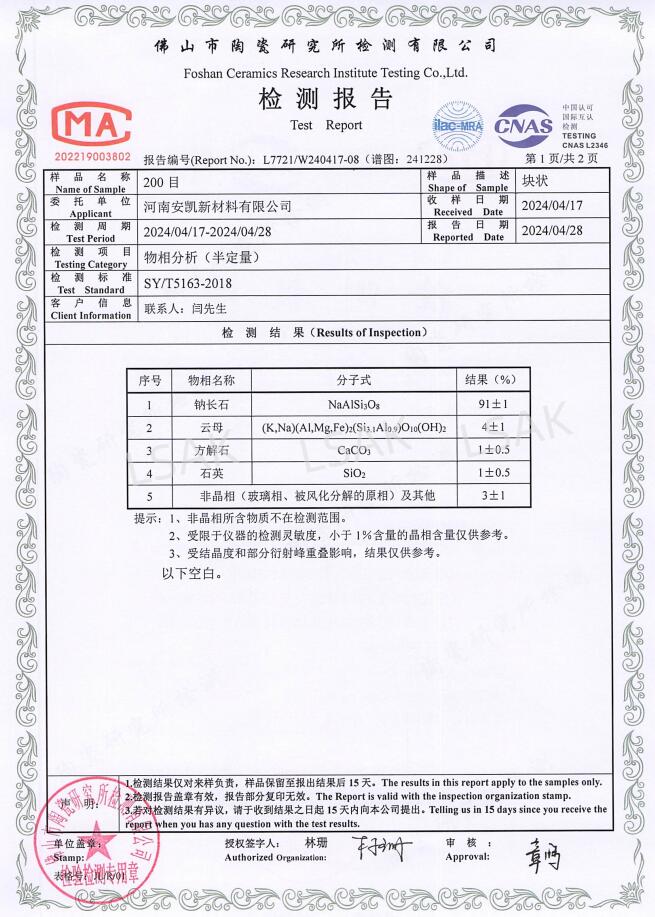

Firstly, the molecular formula of sodium feldspar is NaAlSi3O8. Ideally, its purity can reach 90%, with LS’s sodium feldspar even closer to the theoretical value (91±1). This indicates that under appropriate processing conditions, sodium feldspar can achieve higher purity, providing a foundation for its applications.

Secondly, the mica present in sodium feldspar belongs to silicates, and for sodium feldspar, mica is considered a harmful substance. However, in the glass industry, the mica content requirement is relatively low, so its impact can be negligible. In the ceramic glaze industry, people believe that the lower the mica content, the better, because mica may affect the performance and color of the glaze. Therefore, reducing the mica content is considered an advantage in this industry. The mica content in LS’s sodium feldspar is only 4±1.

Thirdly, the calcite present in sodium feldspar belongs to impurities. The presence of calcite may have certain effects on the performance of sodium feldspar, so attention and control are needed during the production process.

Fourthly, sodium feldspar may contain quartz, also known as free silica or crystalline silica. Quartz, as a harmful impurity, may affect the performance and applications of sodium feldspar. In contrast, silicon dioxide is a structural silica, forming minerals with aluminum, sodium, potassium, and other elements, existing in the molecular structure. Structural silica is more easily melted compared to free silica. Therefore, controlling the content of free silica and increasing the content of structural silica helps improve the melting performance of sodium feldspar, increasing its utilization rate in production.

Finally, sodium feldspar may exist in an amorphous phase under certain conditions. The occurrence of this amorphous phase is usually related to higher aluminum content, which may lead to the formation of amorphous or glassy substances after the decomposition of sodium feldspar during melting. Controlling the amorphous phase requires precise control of the raw material composition during the production process to ensure the stability of product quality.

In summary, the above mineral phase analysis results indicate that LS’s sodium feldspar has higher purity and better performance characteristics while also highlighting areas that need attention and improvement. Through precise control and adjustment during the production process, the quality and utilization efficiency of sodium feldspar can be further improved, promoting its widespread application in industries such as glass and ceramics.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.