As the global fiberglass industry continues to expand, manufacturers are increasingly demanding efficient and low-cost fluxes. As a natural mineral flux, sodium feldspar (NaAlSi₃O₈) is gradually becoming an important raw material in fiberglass manufacturing due to its excellent melting properties and cost advantages.

The fluxing effect and technical advantages of sodium feldspar

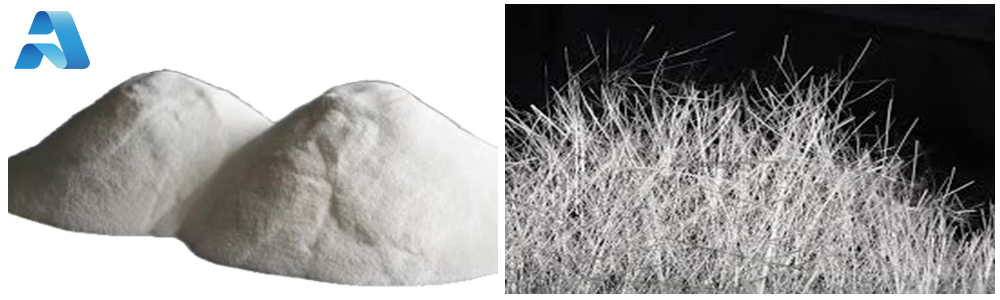

Sodium Feldspar (NaAlSi₃O₈) is a common aluminosilicate mineral with a low melting point, good chemical stability and thermal stability. In the production of glass fiber, sodium feldspar as a flux can effectively reduce the melting temperature, reduce energy consumption, and improve the stability of the melting process. In addition, sodium feldspar also has a good clarification effect, which helps to improve the transparency and purity of glass fiber.

According to relevant research, the method of using sodium feldspar as a fluxing clarifier to produce alkali-free glass fiber can prevent crystal precipitation during the formation of glass fiber, thereby improving product quality and reducing production costs. This method has been patented, showing the wide application prospects of sodium feldspar in glass fiber manufacturing.

Analysis of market drivers

Growing demand for glass fiber: Glass fiber is widely used in wind turbine blades, lightweight automobiles, building reinforcement materials and other fields. According to the Global Market Insights report, the wind power sector will account for 35% of glass fiber demand in 2024, and the rapid development of new energy vehicles will further promote market growth.

Promoted by environmental protection policies: Countries have tightened carbon emission restrictions on high-energy-consuming industries. As a green flux, sodium feldspar has more sustainable advantages than soda ash.

Supply chain localization trend: China, India and other countries have increased their efforts in sodium feldspar mining, reducing their dependence on imported soda ash. In 2024, China’s sodium feldspar production accounted for 40% of the world, making it a major supplier.

Regional market trends

Asia Pacific: China and India are the fastest growing markets for glass fiber production, and the annual growth rate of sodium feldspar demand is expected to reach 6%-8%.

North American market: The development of shale gas in the United States has driven the demand for glass fiber pipes, and the import volume of sodium feldspar has increased year by year.

Europe: Strict environmental regulations have prompted companies to turn to low-carbon fluxes such as sodium feldspar.

Conclusion

As a flux, sodium feldspar is becoming a key driving force for the development of the glass fiber industry with its technical advantages, cost-effectiveness and environmental protection characteristics. Henan Ankai New Materials Co., Ltd. not only meets market demand through high-quality products and continuous innovation, but also injects new momentum into the green transformation of the industry.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.