In the ceramic industry, flux is an important raw material for optimizing the sintering process and improving product quality, and 200 mesh sodium feldspar has become one of the indispensable fluxes in ceramic production due to its excellent physical and chemical properties. Sodium Feldspar (NaAlSi₃O₈) plays a key role in the formulation of ceramic bodies and glazes due to its low melting point, high chemical stability and excellent fluxing properties.

Sodium Feldspar, as a silicate mineral containing alkali metals, promotes the formation of liquid phase by reducing the melting temperature during the sintering process of ceramics, thereby significantly improving the density and mechanical strength of the green body. Its main functions include the following aspects:

Reducing sintering temperature: sodium feldspar begins to soften and form a liquid phase at high temperature (about 1150-1250°C), filling the pores in the green body and reducing the energy required for sintering. According to research, adding 5-15% of 200 mesh sodium feldspar can reduce the sintering temperature of the ceramic green body by 50-100°C, which not only reduces energy consumption but also extends the service life of the kiln.

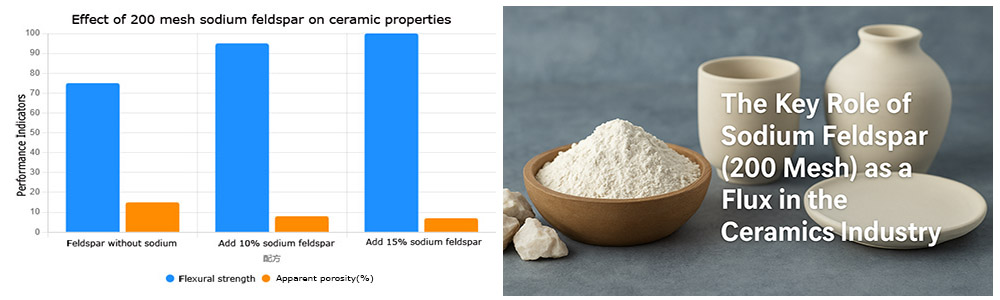

Optimizing green body structure: The liquid phase formed by sodium feldspar during the sintering process can promote the bonding between particles and reduce microcracks and porosity in the green body. Experiments show that the apparent porosity of a green body containing 10% sodium feldspar can be reduced from 15% to about 8%, significantly improving the flexural strength of the green body (up to 80-100 MPa).

Improve glaze quality: In ceramic glazes, sodium feldspar as a flux can effectively reduce the melting temperature of the glaze and improve the fluidity of the glaze, thereby forming a smooth and uniform glaze layer. Studies have shown that the surface gloss of glazes with 8-12% 200 mesh sodium feldspar can be increased by 20%, while reducing defects such as pinholes and bubbles.

Enhance chemical stability: The Na₂O component in sodium feldspar can form a stable glass phase with other oxides in the body, improving the acid and alkali resistance and wear resistance of ceramic products. This is particularly important for the production of high-performance building ceramics and daily-use ceramics.

Compared with other commonly used fluxes, 200 mesh sodium feldspar has the following significant advantages:

Fine particle size and uniform distribution: 200 mesh (about 74 microns) sodium feldspar has a higher specific surface area, which can participate in the reaction faster during the sintering process and improve the fluxing efficiency. Compared with coarser particles (such as 100 mesh), the dissolution rate of 200 mesh sodium feldspar is increased by about 15%, which significantly shortens the sintering time.

Low iron and low impurities: High-quality 200 mesh sodium feldspar is usually selected and purified, and the Fe₂O₃ content can be controlled below 0.15%, avoiding the problem of body or glaze color difference caused by iron oxides. This is crucial for the production of high-white ceramic products (such as sanitary ceramics and high-end tiles).

High cost-effectiveness: sodium feldspar resources are widely distributed and relatively cheap. According to market data, the price per ton of high-quality 200-mesh sodium feldspar is about RMB 800-1,200, which is much lower than imported flux raw materials, providing a cost-effective option for ceramic companies.

Environmentally friendly: As a natural mineral raw material, the mining and processing of sodium feldspar has little impact on the environment, and no harmful gases are released during the sintering process, which is in line with the trend of green manufacturing.

200 mesh sodium feldspar has become the preferred material for flux in the ceramic industry due to its advantages of reducing sintering temperature, optimizing green body structure, improving glaze quality and high cost-effectiveness. Its contribution to energy conservation and emission reduction, improving product quality and reducing production costs has been widely recognized. If you want to know more, please contact Henan Ankai New Materials Co., Ltd.

Whether you have questions or you would just like to say hello,Contact us!

Call Anytime:

+86 15837207537Send E-mail:

info@lsakminerals.comAddress:

Anyang City , Henan Province, China.